Schneiden von Diamantwerkzeugen mit Laser MicroJet

Neue Entwicklungen in der wasserstrahl- geführten Laserbearbeitung von industriellen Diamantwerkzeugen. Beim Laser MicroJet System wird ein Laserstrahl nach seinem Durchgang durch eine druckbelastete Wasser- kammer in eine Düse fokussiert.

By Sébastien Kurzen, Nitin Shankar

As carbon fiber-reinforced polymer (CFRP) and ceramic matrix composite (CMC) materials proliferate in aircraft engines, space components and hypersonic applications, machining becomes an issue where precision and efficiency can alter program outcomes.

By Ginger Gardiner

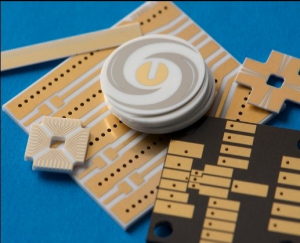

Technology Volume production of high precision tools with new 5-axis LCS 305. Synova’s patented LMJ technology delivers better results than conventional dry lasers and has become a benchmark in the processing of diamond materials.

By Jacques Coderre, Rémi Laure, Amédée Zryd

As fast as laser, as precise as EDM

LMJ guides a laser beam within a hair-thin water jet enabling a long working length. While it remains a thermal technology, the coupling with the water jet enables better local cooling and cleaning. Synova is the pioneer in exploring and commercialising this cool technology.

By Jun Wang and Gerrit Ter Hoek

Drilling of Holes in Ceramic Substrates

Drilling of via holes in ceramic substrates of thin film circuits with LMJ eliminates the hole-cleaning step and reduces cost of ownership versus CO2 lasers.

Cutting of High-Precision Metal Parts

Synova's Laser Cutting System (LCS) 800 was used for job shop of high precision parts. In this case, throughput and flexibility increased while quality remained the same as with etching and electroforming.

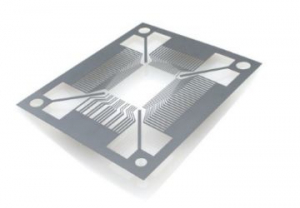

Shadow Mask Patterning

LMJ is used to cut and drill thin nickel masks, so called shadow mask patterning. Nickel foils are challenging to cut/ablate due to the large size and low thickness.

Cutting of Electrical Components

Synova's Laser MicroJet (LMJ) is used to cut difficult-to-machine metal alloys for electrical components reaching high edge quality and accuracy.

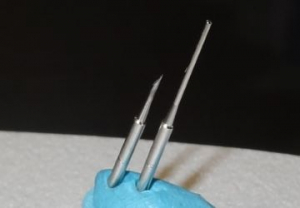

Cutting of Platinum Electrodes

The main challenge to cut platinum electrodes is to reach to the electrode which is welded more than 20mm deep in a cylinder. Processing with LMJ is much faster than with EDM.

High-Tech Components

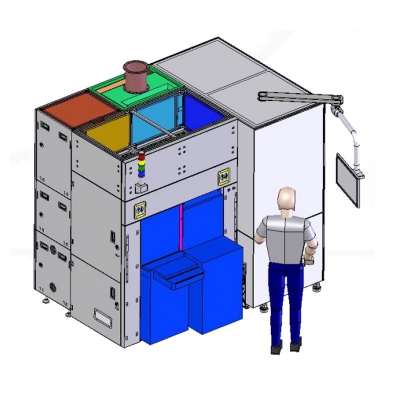

LDS (Laser Dicing Systems)

LDS 300 M

The Laser Dicing System is primarily designed for semiconductor back-end processing; mainly wafer dicing and scribing applications. The LDS 300 M requires manual loading. Wafer alignment and kerf check are performed automatically. Synova’s new 300 mm (12”) wafer dicing system integrates a maintenance free fiber laser.