Laser MicroJet Benefits

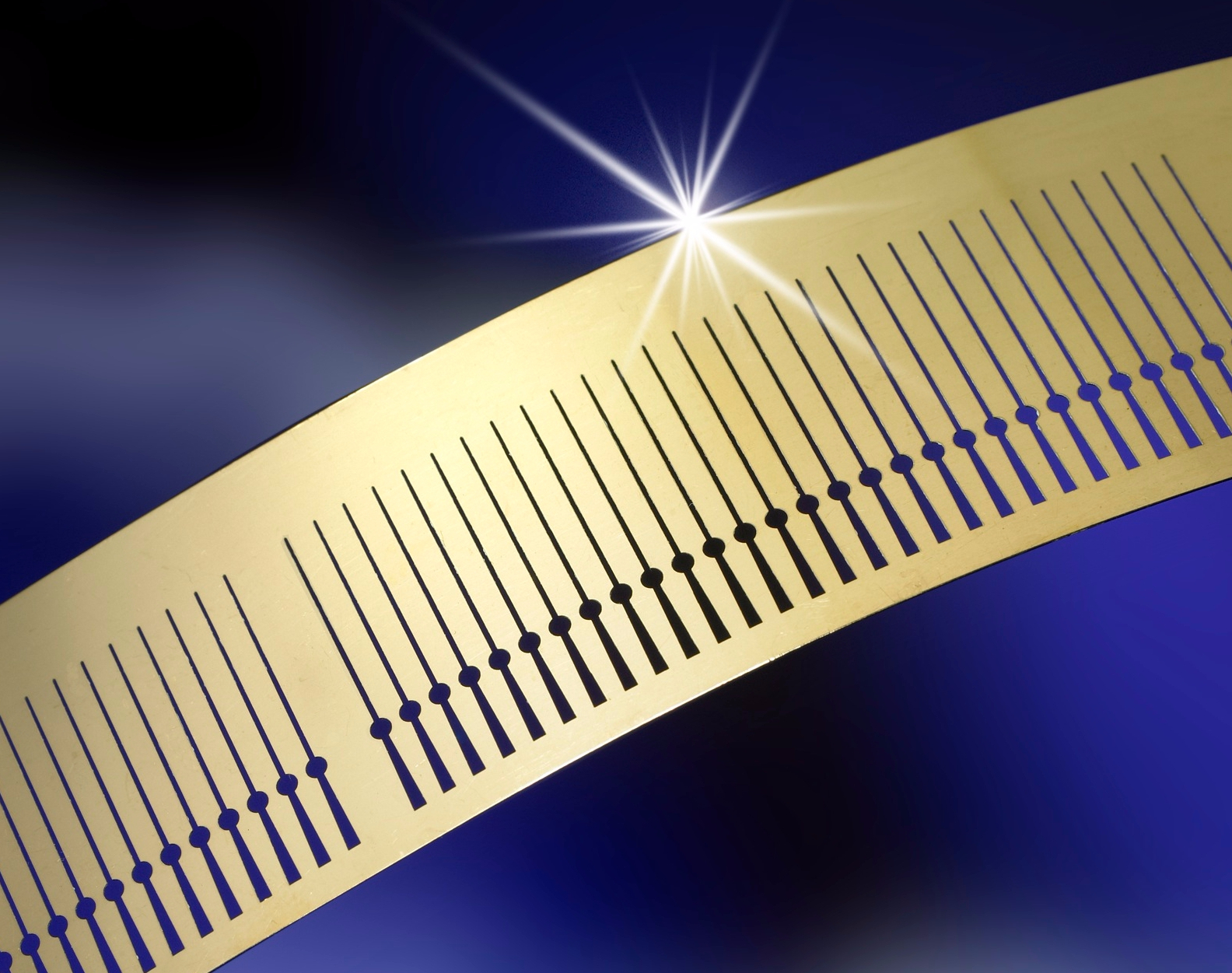

Synova’s advanced Laser MicroJet (LMJ) systems with 3 or 5 axes are ideally suited for cutting watch movement components and decorative parts with high precision and quality as needed for the watch industry.

The water jet guided laser technology can be used to improve the cutting process presently in place in the watch industry. Typical methods are dry laser, EDM, stamping or micro-machining. But all these technologies have their particular limitations in terms of heat damages, process time, flexibility or variety of shapes.

The LMJ technology combines the advantages of the high energy pulsed laser with a hair-thin water jet. While the laser is used for material ablation, the water jet is used for guiding the laser light, cooling the edges and preventing the sample from particle contamination.

The LMJ therefore provides a suitable technique for the cutting of thin metals such as brass, stainless steel, Durnico® or copper alloys such as CuBe that are extremely susceptible to thermal effects. It enables excellent cutting quality free of mechanical stress, heat damages and chipping. The water jet prevents contamination and burrs especially at the backside of the cut thus reducing the time for post-processing of fragile components and increased parts’ yield.

Generally to achieve a high-level of quality, pieces are cut in one pass with a cutting speed ranging from 0.1 mm/ s to few mm/ s depending on the thickness. The LMJ cuts in any direction and thus any contour is possible even very sharp angles.

LMJ machines are a valuable addition to traditional machining solutions especially for the manufacture of watch prototypes, small and medium-sized series of high-end watches. They can also be automatized for a continuous production. The efficient and precise LMJ systems enable very low running costs as there is no tool wear.

Main Applications

- Cutting of functional parts (Watch movement components)

- Wheels and toothed wheels

-

A. Wheel

A. Wheel

A. Wheel

A. Wheel

-

B. Escape wheel (CuBe)

B. Escape wheel (CuBe)

B. Escape wheel (CuBe)

B. Escape wheel (CuBe)

-

C. Gear (brass)

C. Gear (brass)

C. Gear (brass)

C. Gear (brass)

-

D. Second wheel (German silver)

D. Second wheel (German silver)

D. Second wheel (German silver)

D. Second wheel (German silver)

-

E. Second wheel - Back

E. Second wheel - Back

E. Second wheel - Back

E. Second wheel - Back

-

F. Second wheel - Front

F. Second wheel - Front

F. Second wheel - Front

F. Second wheel - Front

-

G. Wheel (brass)

G. Wheel (brass)

G. Wheel (brass)

G. Wheel (brass)

View the embedded image gallery online at:

https://synova.bebold.ch/applications/watchmaking.html#sigProIdf25fa80e9b -

- Springs, jumpers and levers

- Oscillating masses, bridges

2. Cutting of decorative parts (External watch components)

- Hands

-

A. Watch hands

A. Watch hands

A. Watch hands

A. Watch hands

-

B. Watch hands (brass)

B. Watch hands (brass)

B. Watch hands (brass)

B. Watch hands (brass)

-

C. Watch hands (brass)

C. Watch hands (brass)

C. Watch hands (brass)

C. Watch hands (brass)

View the embedded image gallery online at:

https://synova.bebold.ch/applications/watchmaking.html#sigProIdc88d273067 -

- Dials and dial components

View the embedded image gallery online at:

https://synova.bebold.ch/applications/watchmaking.html#sigProId3aa77382e8 - Wristlet components and other decorative parts

View the embedded image gallery online at:

https://synova.bebold.ch/applications/watchmaking.html#sigProId349a55878c

Optional automatization LMJ machines

- Automatic band feed

- Pick and place robot

Customer Sample Request Form

If you are interested in seeing how the Laser MicroJet® can improve your manufacturing processes, please send us a short description of your application (material, thickness, process, requirements).

Therefore please use the electronic form CSRF available in English, German or French:

Testimonial

"Your technology and its potential to manufacture watch components is the most beautiful thing I saw during that exhibition."

(Gillèron, Switzerland)