Kalte Laser zum Schneiden von CVD-Diamanten

Die LCS Familie von Laser-Schneidmaschinen, die mit dem LMJ ausgestattet sind, kombinieren den Vorteil des Wasser- und Laserschneidens in einem Vorgang. Diese Lasermaschinen sind in der Lage, sehr harte synthetische Diamanten in Scheiben zu schneiden.

By Nitin Shankar

Laboratory Grown Diamonds for Industrial Application

The Synova LCS (Laser Cutting System) family of machines equipped with the patented Laser MicroJet combines the advantage of both water and laser cutting in one operation. This laser can slice hard synthetic diamonds for use as cutting tools with smooth edged surfaces.

By Nitin Shankar

Wet Laser Machining for Industrial Diamond Tools

Over 30 wet lasers are now running for "sawing" gem diamond in India, Belgium, Thailand, Russia and South Africa. There are many application areas for the wet laser from drilling holes in ceramic coated, superalloy turbine blades to cutting gears for luxury watches.

By Dr. Peter J. Heath, Mr. Sébastien Kurzen

CVD-Diamanten für Werkzeugeinsätze

Die Synova LCS Familie, die mit dem patentierten Laser Microjet ausgestattet sind, kombinieren den Vorteil von Wasser- und Laserschneiden in einem neuen Prozess. Diese Lasermaschinen können synthetische Diamanten in Scheiben schneiden.

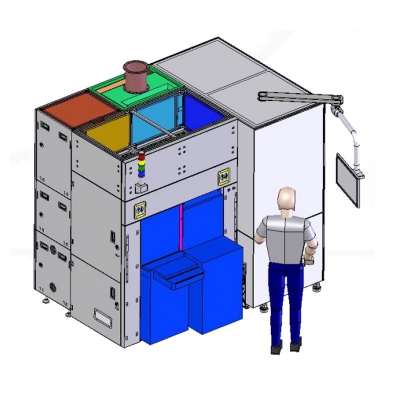

HybridCell for Turbine Blade Hole Drilling

EDM and laser are the two proven technologies for drilling precision holes. Makino and Synova have developed a hybrid cell, combining both technologies to offer the ideal solution for drilling tapered or funnelled holes in turbine engine components.

By Nitin Shankar

Cutting Diamond Tools by Laser MicroJet

LMJ Process: In the Laser MicroJet system, a laser beam, passing through a pressurized water chamber, is focused into a nozzle. The low-pressure water jet emitted from the nozzle guides the laser beam by means of total internal reflection at the water/air interface.

By Sébastien Kurzen, Nitin Shankar

Plant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production. GE Aviation (Evendale, OH, US) has spent more than US$1.5 billion to bring to market ceramic matrix composites that can be mass produced. The quantity of CMC raw material GE uses has increased twenty-fold.

By Ginger Gardiner

Laser Machining of Diamond Tools

Artificial diamond cutting tools are replacing tungsten carbide and ceramic composites where high quality surface finishes are required. Only laser technologies are capable of machining such materials, which are (like some ceramics) as hard as natural diamonds.

By Nitin Shankar

Ciselage fin de composites ou de diamants

Le secret des machines Synova: la maîtrise du feu et de l'eau pour la découpe de diamands. En effet par la conjonction d'un faisceau laser contenu dans un jet d'eau les diamants peuvent désormais être finement taillés. Mais les horlogers peuvent aussi tirer parti de cette technologie.

By Jean-René Gonthier

Cutting Diamond Tools by Laser MicroJet

Developments in Wet Laser Machining of Industrial Diamond Tools. Artificial diamond materials replace tungsten carbide and ceramic composites in cutting tools when high surface finish quality is required. Nozzle materials go from lower end PCD to high-end SCD.

By Sébastien Kurzen, Nitin Shankar

LDS (Laser Dicing Systems)

LDS 300 M

The Laser Dicing System is primarily designed for semiconductor back-end processing; mainly wafer dicing and scribing applications. The LDS 300 M requires manual loading. Wafer alignment and kerf check are performed automatically. Synova’s new 300 mm (12”) wafer dicing system integrates a maintenance free fiber laser.