Cutting of Oscillating Parts

The LMJ is used to cut oscillating monolithic parts with complex shapes without deformation or heat affected zone but with the capacity to cut very thin bridges.

Cutting of Watch Components for Luxury Watches

With very short warm-up and set-up times Synova's Laser MicroJet (LMJ) is a flexible and stable tool to cut watch components for luxury watches, no matter if it's for production or prototyping.

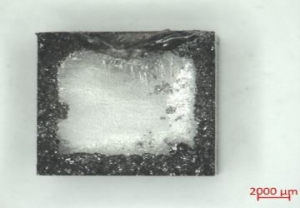

CVD Seed Slicing

The challenge was to slice large CVD crystals (chemical vapor deposition) of up to 25 mm from a single direction and along the largest thickness, with a high quality.

Lab Grown Diamond Material for Industry

The LMJ is used for cutting components with free froms with high accuracy requirements (± 5 μm) from CVD crystals.

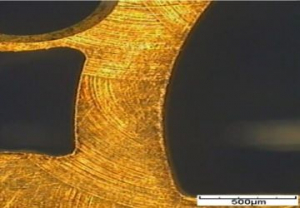

Coring for Graphite Removal

The use of LMJ ensures a high quality coring and slicing process of CVD crystals and smooth surfaces as well as low roughness what requires minimal post treatments.

Coring and Slicing of a CVD Crystal

With LMJ there was an improvement in yield, straightness, smoothness, cracks, and throughput in coring and slicing CVD crystals.

Slicing of a HPHT Diamond

The goal is to get a maximum number of slices out of the HPHT crystal (high pressure, high temperature) and to cut variable thicknesses ranging up to 12 mm.

Slicing of a CVD Crystal

The aim is to obtain a maximum number of slices from the CVD crystal. Cutting with a constant parallel kerf and without tapering with LMJ ensures a higher yield.

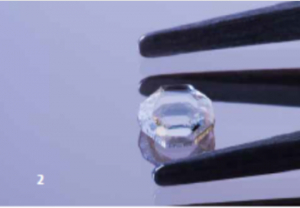

Fancy Bruting

The LMJ is advantageously for fancy bruting due the its perfect cut at the outline of the diamond to create the shape profile. Less post-processing is required.

Hole Drilling for Jewellery

To link the diamond with the other jewellery part, a hole-drilling process might be required. With LMJ the drilled holes are fully straight, no V-shape, no chipping at the hole entry and exit.

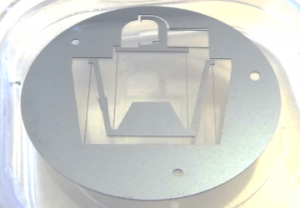

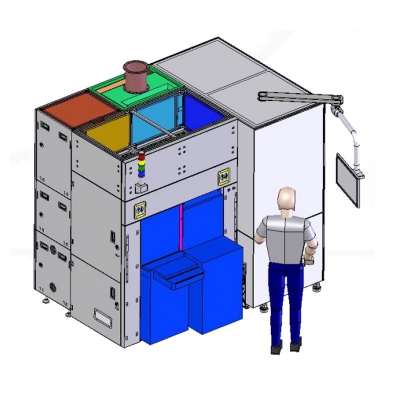

LDS (Laser Dicing Systems)

LDS 300 M

The Laser Dicing System is primarily designed for semiconductor back-end processing; mainly wafer dicing and scribing applications. The LDS 300 M requires manual loading. Wafer alignment and kerf check are performed automatically. Synova’s new 300 mm (12”) wafer dicing system integrates a maintenance free fiber laser.