Cutting of IGTB Power Chips

LMJ is the perfect choice to cut silicon carbide which is a challenging material to cut because of its hardness and brittleness. In this case it is used for IGTB Power Chips.

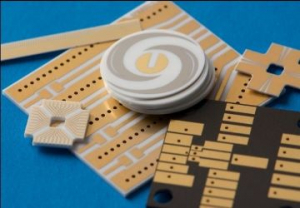

Drilling of Holes in Ceramic Substrates

Drilling of via holes in ceramic substrates of thin film circuits with LMJ eliminates the hole-cleaning step and reduces cost of ownership versus CO2 lasers.

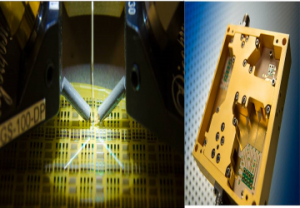

Wafer Dicing

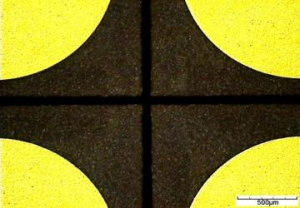

Dicing of Ceramic Circuits

With LMJ, it was possible to establish a repeatabel, high-speed process for singulating substrates without damaging the adjacent circuitry.

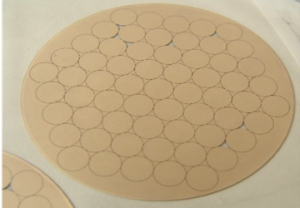

Singulation of Silicon Wafers

| The LMJ is used for hexagonal square or circular dies singulation for PressFIT Diodes and achieves a much better edge quality compared to grinding. |

Downsizing of Silicon Wafers

The LMJ is used for gentle, precise, and fast processing for large inline production of power semiconductor devices. Low contamination of the workpiece is crucial.

Cutting of Nitinol Stents

LMJ was the perfect choice to receive a controlled/homogeneous roughness, narrow tolerances, no HAZ, and no reduction in strength cut cardiovasculaire stents.

Cutting of Silicon Blades

The silicon blades for the first single-use, safety engineered surgical knife designed for use in cutting corneal tissue were cut with Synova's LMJ.

Micro-Machining of High-Tech Parts

The LMJ is used for micromachining of high-tech parts reaching top quality/tolerances and better return on investment.

Cutting of Watch Dials and Markers

LDS (Laser Dicing Systems)

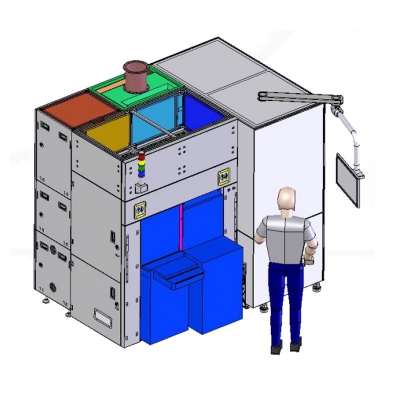

LDS 300 M

The Laser Dicing System is primarily designed for semiconductor back-end processing; mainly wafer dicing and scribing applications. The LDS 300 M requires manual loading. Wafer alignment and kerf check are performed automatically. Synova’s new 300 mm (12”) wafer dicing system integrates a maintenance free fiber laser.