143.45 Carat Diamond

This expensive and valuable diamond has been cut to perfection. Laser MicroJet technology ensures minimal weight loss thanks to parallel cutting.

The Constellation

The 813-carat Constellation Diamond is the most expensive rough diamond in the world. The resulting 313-carat ‘Constellation One’ is the largest D color emerald cut diamond ever.

The Queen of Kalahari

The 342-carat rough diamond has resulted in a set of 23 diamonds, the Garden of Kalahari. Highest precision could be achieved thanks to LMJ.

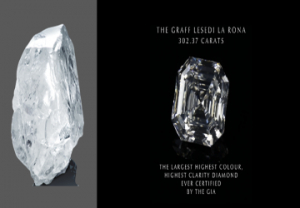

The Graff Lasedi La Rona

The Graff Lasedi La Rona is the largest highest color, highest clarity diamond ever certified by the GIA. Thanks to parallel cutting with LMJ the weight loss is minimal.

Super Hard Tool Making

Synova's Laser MicroJet's (LMJ) higher quality 3D machining of inserts and complex multi-tip tools enables new applications with better operating cost.

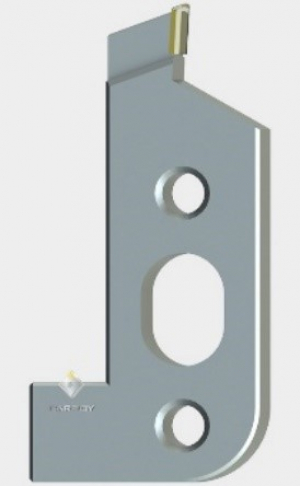

Cutting PCD and CBN Tools

Cutting PCD, CBN tools: no micro cracks, HAZ, oxidation possible with LMJ. Verticality, narrow tolerances, low roughness, and sharp edges.

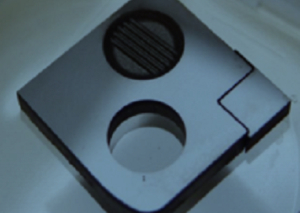

Pre-Cutting of Tool Inserts

When using LMJ to cut diamond tool inserts 99% of the diamond material can be removed at high speed before a final polishing step.

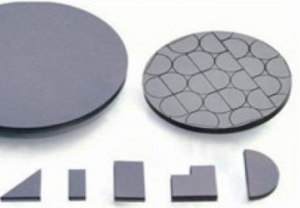

Cutting of Binderless Polycrystalline Diamond

Fabricating top quality discs made of Binderless Polycrystalline Diamond with LMJ is less time- and tool-consuming than with conventional methods such as grinding.

Cutting of CBN Blanks without Heat Damage

When cutting CBN (Cubic Boron Nitride) blanks with LMJ the result exceeds the quality of dry laser cutting as heat damages and rough edges are avoided.

Drilling of Gas Turbine Blades

Drilling of industrial gas turnine blades by avoiding heat related problems and maintaining high productivity by the use of LMJ.

LDS (Laser Dicing Systems)

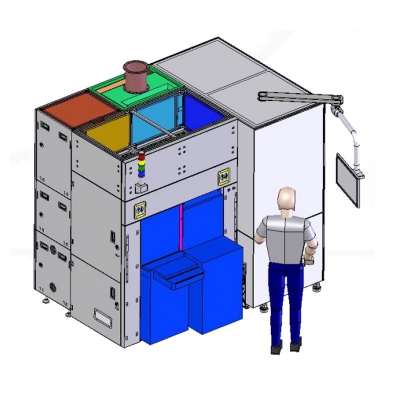

LDS 300 M

The Laser Dicing System is primarily designed for semiconductor back-end processing; mainly wafer dicing and scribing applications. The LDS 300 M requires manual loading. Wafer alignment and kerf check are performed automatically. Synova’s new 300 mm (12”) wafer dicing system integrates a maintenance free fiber laser.