Displaying items by tag: Semiconductors and Photovoltaics

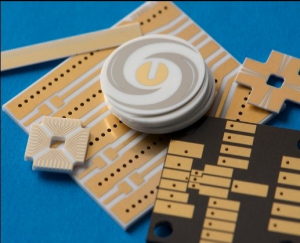

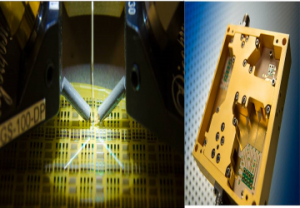

Drilling of Holes in Ceramic Substrates

Drilling of via holes in ceramic substrates of thin film circuits with LMJ eliminates the hole-cleaning step and reduces cost of ownership versus CO2 lasers.

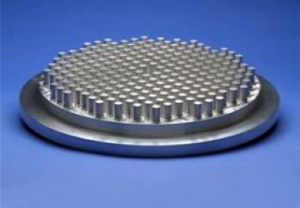

Semiconductor Reactor Sub-Assemblies

LMJ is used for micro-machining semiconductor reactor sub-assembly parts with tight tolerances on thick, hard materials in contact with reactive gas.

Cutting of LED Chips

LED chips and packages are made of materials that are frequently difficult to cut mechanically. With LMJ one has high flexibility regarding materials and shapes.

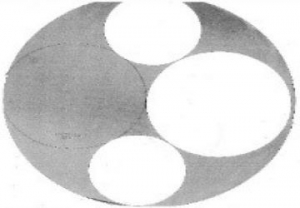

Chamfer Cutting

LMJ is used to downsize 450mm silicon semiconductor wafers to 300mm and 200mm wafers, without any impact on the material.

Cutting of Platinum-Iridium

LMJ was chosen to dice sensitive platinum-iridium detectors in the form of microchips, it has several advantages over blade sawing.

Taiko Ring Removal

Thin wafers are challenging to manipulate and to process due to the high flexibility and fragility. With LMJ the perfect TAIKO ring removal becomes possible.

Complementary Metal Oxide

|

Silicon frames are very brittle and request a gentle processing technology without any micro cracks and chipping. LMJ reaches high accuracy, straight walls, low roughness and is highly flexible. |

Edge Trimming of CMOS Image Sensors

LMJ is used to trim edges of CMOS image sensors and proves superiority over EDM by significantly higher quality.

Cutting of IGTB Power Chips

LMJ is the perfect choice to cut silicon carbide which is a challenging material to cut because of its hardness and brittleness. In this case it is used for IGTB Power Chips.