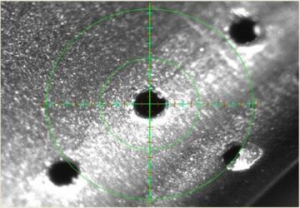

Drilling of Turbine Blades

Synova's Laser MicroJet (LMJ) was used to drill cooling holes in turbine blades in coated superalloy. Chipping or micro cracking of the coating can be avoided thanks to this gentle process.

All 57 facets of the diamond are cut in a single operation. The breakthrough sensor recognizes when a facet cut is complete and then automatically initiates facet changing. Cut offs are collected instead of polished away. The result is a fully shaped round brilliant.

Cutting a 5 mm Hole in Thick Superalloy

Synova's LMJ is used to cut a 5 mm hole in 10 mm thick superalloy: Superalloy thickness: 10 mm; Laser power: 40W in the water jet; Roughness: RA 0.7um ISO 4287; Cycle time: 4 min 30 sec; Taper angle: 0.036°.

This video shows how cutting 1 mm diameter holes in 8 mm thick polycrystalline silicon using Synova Laser MicroJet®.

Cycle time: 22 seconds

Taper angle: 0.036°

Cutting Hexagons in 18 mm Thick Aluminium

This video shows how hexagons with a total lenght of 3 mm are cut into 18 mm thick aluminium using Laser MicroJet.

The side length is 1.73 mm and the cycle time is 2 min 50 secs.

Cutting 1 x 1 mm Squares in Thick Stainless Steel

Synova Laser MicroJet® is used to cut squares in 5 mm thick stainless steel.

The cycle time is 40 seconds.

LMJ used to cut a contact ledge from a cubic boron nitride (CBN) block. The video nicely demonstrates multiple operations in a single process: cutting, drilling, 5-axis chamfering and profiling. Initial dimensions of the CBN block: Size: 12 x 7 mm; Thickness: 5 mm.

The Constellation Diamond cut with Synova’s DCS 300

The world’s most valuable rough diamond (813 carat) was cut on a Synova DCS 300. Its LMJ technology ensures high precision, no heat damage, parallel kerfs, smooth cutting surfaces, sharp edges and minimal weight loss.

The extremely compact LCS 50 with 3 or 5 axes has been designed for small work pieces such as diamond tools, watch components and other small work pieces that require precision cutting, drilling, grooving or slicing.

Cutting of 813-Carat Gemstone with Synova's DCS 300

Watch this viedo to see how the 6 cm long “Constellation Diamond” was laser cut with Synova’s Diamond Cutting System DCS 300. Thanks to LMJ technology, parallel kerf walls are achieved and weight loss is minimized.