LCS 303 - Cutting Thin Ceramics (Alumina)

The 3-axis LCS 303 is a highly accurate and reliable laser cutting system. Applications include high precision machining of watch components, medical devices, and electronic parts. Watch this video to see how a 0.7mm thin piece of ceramic (alumina) is cut.

This video shows the cutting, faceting and turning functions of the LMJ with the DCS 50, forming an PCD circular saw blade within 2 hours, which is 3 times faster than a conventional laser could do.

25 Years of Synova - Cutting Anniversary Seal Stamp

To celebrate our company anniversary we cut the anniversary logo out of 6 mm thick brass. Watch this video to see how to cut a seal stamp with our DCS 50.

Cutting Fine Geometries with Hair-Thin Walls

This video shows fine 5 x 3 mm geometries with hair-thin walls being cut into a 1 mm thick copper plate using the LCS 303.

Edge Trimming of SiC Boule

This video shows the edge trimming of a 20 mm thick Silicon Carbide (SiC) Boule, reducing its diameter from 150 mm to 148 mm using the LCS 300.

Fine Cutting in Thick Metals - Spinnerets

The hybrid LMJ method combines a laser with a hair-thin water jet. The cylindrical beam can be guided over a large working distance of up to 100 mm, enabling parallel high aspect ratio kerfs. This video shows fine cutting in thick metals with LMJ, namely the cutting of spinneret forms.

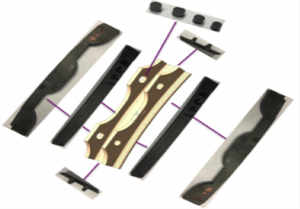

Backstrike Protection With Laser MicroJet

This video explains how to protect backwalls by blowing air or using a water jet to disturb the laser beam after material breakthrough (for parts with difficult access to back walls such as turbine blades) or by using protective material such as Teflon for open parts.

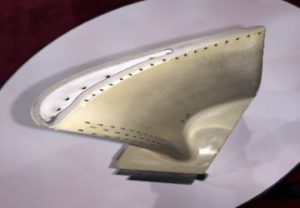

Processing of CMC Shrouds

Synova's Laser MicroJet (LMJ) was used to drill Ceramic Matrix Composite (CMC) shrouds. Laser MicroJet's gentle, precise, and high-volume processing for an exigent aero application is of advantage.

Processing of Aero-Engine Components

High-Speed Drilling of Shaped Holes

High-speed drilling of shaped holes in blades and vanes with LMJ for industrial gas turbines, no thermal stress and minimal recast.