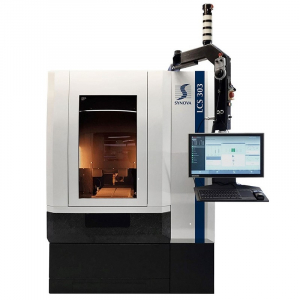

LCS 303

The 3-axis LCS 303 is a highly accurate and reliable laser cutting system. It can process a wide variety of materials, from metals to ultra-hard and brittle materials such as diamond or ceramic, to complex composites. Applications include high precision machining of watch components, medical devices and tools, electronic and other high-tech parts.

DaVinci Diamond Factory

"DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets in a single process. The DaVinci system also allows fancy shaping.

Laser Machining Center LCS 305 in 360 degrees

The Laser MicroJet system with full 5-axis capability can process complex three-dimensional geometries.

Applications include for example the machining of industrial diamond employed in toolmaking as well as superalloys and various composite materials (CMC, CFRP) used in aerospace.

The LCS 305 integrates advanced sensor technology to improve process control (automatic jet angle correction, automatic jet positioning, laser power meter, breakthrough sensor etc.).

Watch the video and learn more about the high-precision LCS 305 in 3D.

At Synova we have been closely following the developments surrounding the spread of the Coronavirus/COVID-19 in Switzerland, Europe and the rest of the world. Synova is taking the situation very seriously and has implemented preventive measures directed by the Swiss Federal Council to protect the health of its employees, customers and partners while ensuring the continuation of our business operations.

At our corporate headquarters and production facility we are following the sanitary recommendations issued by the Federal Office of Public Health (FOPH) in Switzerland. We are continuously informing our employees about measures on how to protect themselves and others from getting infected at the workplace or outside.

Employees are instructed to strictly respect social distancing rules and to favor video conferencing instead of physical meetings with colleagues or partners. Personnel that is not required onsite and staff members at high risk are assigned to work from home.

As many countries remain in lockdown and travel restrictions apply, most of our field service engineers are currently working from the headquarters. Together with our local service team they continue supporting our customers via phone, e-mail or internet using remote diagnostic systems installed in all Synova machines. Due to existing restrictions and supply shortages, there may be delays (e.g. spare part deliveries) for which we apologize up front.

Rest assured that we will do everything in our power to provide our customers with the best possible support given this extraordinary situation.

Thank you for your understanding and stay safe!

****************************************************************************

You can reach us during our regular business hours by e-mail or phone:

Corporate Headquarters:

+41 (0)21 55 22 600

This email address is being protected from spambots. You need JavaScript enabled to view it.

Helpline (Customer/technical support, spare parts):

+41 (0)21 55 22 643

This email address is being protected from spambots. You need JavaScript enabled to view it.

If you are based in the USA, India, Japan or Korea and need assistance, please contact our local subsidiaries (MMCs).

Synova‘s Laser MicroJet: Shaping the future

Click to learn about the working principle, benefits and application areas of this “wet” laser technology.

XLS 1005

The XLS Laser Cutting System integrates Synova’s state-of-the-art Laser MicroJet® (LMJ) technology with a wide machine platform and table for large work pieces. The 5-axis XLS 1005 with optional C2 rotary axis allows high-precision 2D and 3D machining of metals and ceramics, free of heat affected zone (HAZ) and burrs.

Laserstrahl mit Kühleffekt

Um die Effizienz von Flugzeugturbinen zu verbessern, werden zunehmend leistungs- fähigere Werkstoff-Komposite verwendet. Beim Fertigen der immer ausgefeilteren Kühl- bohrungen zeigt der wasserstrahlgeführte Laser seine Stärken.

By Nitin Shankar

New Corporate Headquarters in Duillier

Synova is excited to announce that it recently moved into larger, more modern premises in Duillier, halfway between Geneva and Lausanne. The new 2300 square meter facility offers extended production capacity and a state-of-the-art application laboratory.

Our application engineers and a total of six Laser MicroJet demo machines are available for feasibility tests, application development and demonstrations. Two machines are entirely dedicated to cutting jobs such as prototypes or small-batch parts.

The building - formerly used by the watch industry - has been entirely renovated and equipped with a new façade. The new premises include a luminous production hall and showroom in the heart of the building as well as generous office space in the adjacent wings. Our new location is close to the city of Nyon in the canton of Vaud, only 20 minutes away from the Geneva airport and easily accessible from the main highway.

Please note our new address and phone number:

SYNOVA S.A.

Route de Genolier 13

1266 Duillier

Switzerland

Phone: +41 21 55 22 600

Email addresses remain unchanged. Feel free to contact us with any questions you may have concerning our new location or services.

We look forward to serving you from our new address!

New Company Location as of Dec.12: Synova Is Moving Its Corporate Headquarters to Duillier

In order to expand our production capacity and provide a better service to our customers, Synova will relocate into larger and more modern premises in Duillier mid-December 2016. Our new location is close to the city of Nyon in the canton of Vaud, only 20 minutes away from the Geneva airport and easily accessible from the main highway.

To minimize disruption, we have arranged the move from December 12th to 14th, 2016. We will be fully operational again Thursday, December 15th. We thank you in advance for your understanding and apologize for any inconvenience this change may cause.

Please note our new address as of December 12th:

SYNOVA S.A.

Route de Genolier 13

CH-1266 Duillier

Switzerland

Phone (NEW): +41 21 55 22 600

We kindly ask you to update your records accordingly. Email addresses will remain unchanged. Feel free to contact us with any questions you may have concerning our new location or services.

We look forward to serving you from our new address!