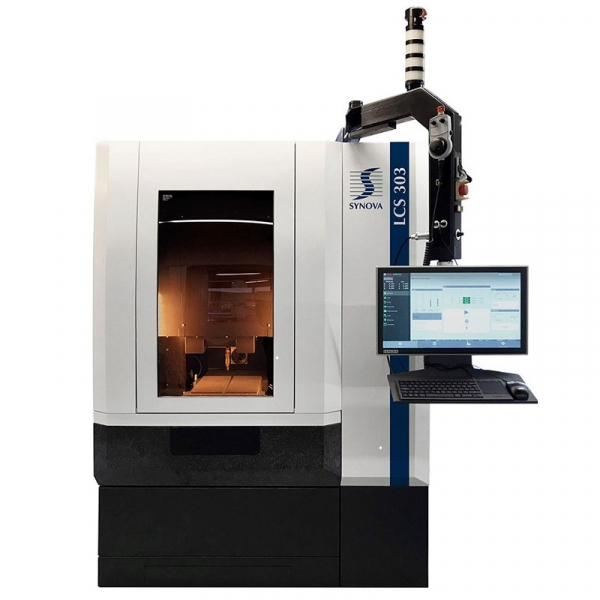

The 3-axis LCS 303 is a highly accurate and reliable laser cutting system. It can process a wide variety of materials, from metals to ultra-hard and brittle materials such as diamond or ceramic, to complex composites. Applications include high precision machining of watch components, medical devices and tools, electronic and other high-tech parts.

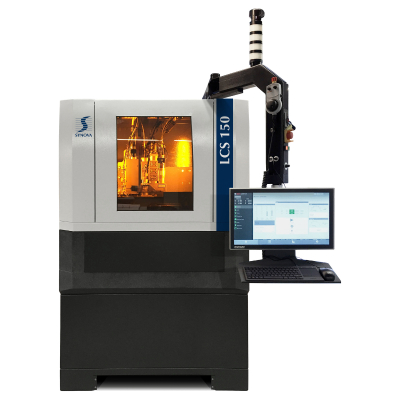

LCS (5)

The 3-axis laser cutting machine LCS 800 with integrated Laser MicroJet® technology is a robust and versatile system conceived for a multitude of high-precision cutting and drilling applications in different industrial sectors. The large mounting table allows machining of virtually any part size and is suited for small series and prototypes but also for large volumes.